- Small footprint occupies less than 15% of the area of traditional surface storage systems

- Lower capital cost: 20% to 40% less than tunnels or basins

- Simple shaft geometry minimizes head loss, allowing gravity operation and eliminating the need for booster pump stations

- Eliminates tunnel and associated drop shafts, riser shafts, construction shafts, and ventilation structures, as well as surge control tanks and screening buildings

- Eliminates water infiltration and associated treatment costs

- Eliminates manual disposal of screenings

- Automated operation and lower O&M requirements than basins or tunnels.

- Lower construction risk

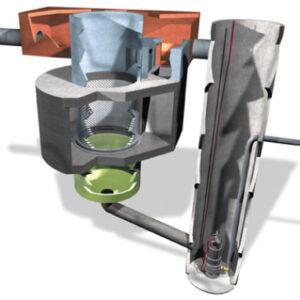

Treatment Shaft

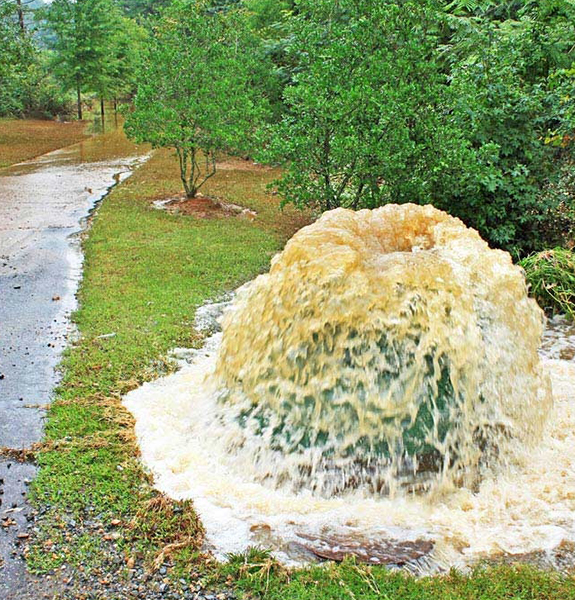

The Treatment Shaft Technology is ideal for CSO Applications. CSO Treatment shafts can be built using various methods such as slurry wall, diaphragm wall, sinking caisson, tangential pile, secant pile, and sheet pile. The technology provides disinfection contact time, vessel flushing, air venting, odour control, surge control, skimming, settling and fine screening in a compact structure suited for urban sites.

We have partnered with Process Wastewater Technologies to develop a fully-automated, patented vertical treatment shaft process for CSO control systems.