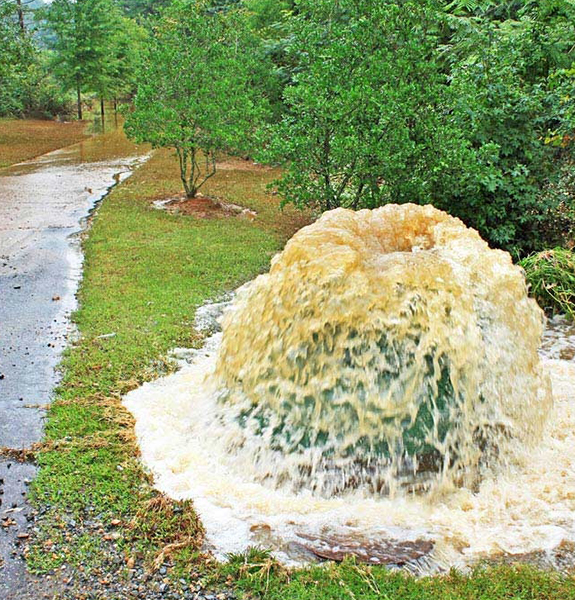

Vortechs – Shallow Profile Hydrodynamic Separator

The Vortechs system is a vault-style hydrodynamic separator for treating stormwater runoff. The Vortechs system combines swirl concentration and flow controls into a single unit for removing fine particles and other pollutants. It utilizes a four stage chamber design (swirl, floatables, flow control, and outlet chambers) with a special baffle and weir design to effectively remove sediment, litter, debris and hydrocarbons.

All Vortechs systems maintain a shallow profile – typically one meter below invert – making the system ideal for applications with high groundwater, bedrock or utility conflicts. Vortechs offers the largest treatment zone surface area of any swirl concentrator systems available allowing removal of particles down to 50 µm in size.