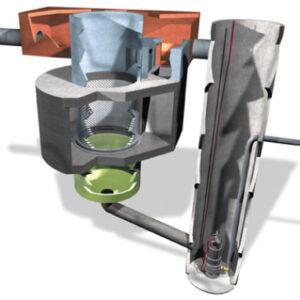

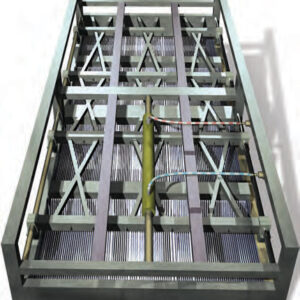

The PWTech® Volute Dewatering Press has been installed to handle a wide range of sludges. It is especially useful when sludges have a high oil and fat content that would bind filter materials. Types of sludge the Dewatering Press has been utilized to dewater:

- Waste biological sludges (including WAS, fixed film, MBR, aerobic and anaerobic digested)

- Potable water sludges (including alum, ferric, and PAC sludges)

- DAF float from slaughter houses and other agricultural processes

- Oil sludge from machining operations

- Wastes from textile processing

- Food processing and wash-down wastes